INVESTMENT PROVIDES INCREASED SCOPE

The large measuring envelope of the new Xcel 9159 CNC coordinate measuring machine gives it unrivalled versatility enabling Jet to satisfy inspection needs in two distinct areas;

enabling Jet to satisfy inspection needs in two distinct areas;

1. It is capable of inspecting high volumes with full SPC quality control.

2. It can inspect large 3D models with complex surfaces.

So for an aerospace customer for example, a hundred blades can be loaded on the table all at once and the machine will then move round and inspect each blade one at a time producing an individual statistical report. At the other end of the spectrum, a large one off model can be inspected by the same machine with the same speed and accuracy. Since its recent introduction, Jet has witnessed surplus inspection capacity, an area that historically operated at maximum capacity. The company is now able to offer additional scope for sub contract inspection work for those customers requiring rapid inspection of complex parts. Interested parties should contact Mark Kirby (Managing Director) or Dave Exton (Quality Manager).

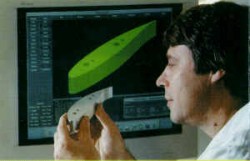

Fast planes and fast cars are well known territory for Jet Blades, but when they were approached by

Bruce Bursford to help work on a British project to both design and produce the worlds fastest bicycle, it was a challenge they could not resist.

Several hundred design hours later, the master patterns were machined from which the moulds would be made to produce perhaps the sleekest, most aerodynamic bicycle ever conceived, capable of speeds in excess of 200 m.p.h.

The bike, currently being tested, is due to go into production later this year.

DUAL CELEBRATIONS FOR NEIL

Neil Matts, our newly promoted CAD/CAM Manager, is also celebrating 20 years with the company this year. Commenting on his promotion, he said, “Although many things have changed over the past twenty years, the constant pace of technological change means that there is never a dull moment My previous role as CNC Supervisor has given me plenty of hands on machine setup and precision machining experience, but I now have the added dimension of responsibility for generating the programming for manufacture. Who knows what the next twenty years hold in store!”

ON THE MOVE

Jet Blades is pleased to announce the internal promotion of Dave Exton to Quality Manager. Dave, who has been with the company for over 8 years, will bring with him a wealth of experience in quality control and inspection.

Brown & Sharpe Xcel CMM

Apart from its accuracy and large measuring capacity there is nothing “extraordinary” about the Brown & Sharp Xcel 9159 Co-ordinate Measuring Machine recently acquired by the company, but the software driving the machine is quite revolutionary and Jet Blades are one of the first U.K. subcontractors to take advantage of it.

PC-DMIS, developed in America, is an awesome software package. Managing Director Mark Kirby was finally  convinced of its pedigree by the fact that the Ford Motor Company have recently selected it to be installed in all their plants world-wide. But what attracted him to it initially was its very powerful capabilities for inspecting complex surfaces and comparing machined results directly to a CAD Master Model. Put in simple terms, a customer designs a part on his CAD systems and supplies Jet with a CAD master model. That model is used in 2 ways. Duct software uses the model to generate 3D machining instructions to manufacture the part at the relevant CNC Machining centre. Simultaneously PC DMIS software uses the same CAD model to inspect the machined part, automatically generating CAD “nominal” data, removing what was typically one of the most time consuming and error prone areas of the inspection routine. Benefits of the package are twofold. Saving time allows for faster, more efficient inspection, relieving a bottleneck area and greatly increasing inspection capacity. Secondly since inspection is made against the original customer supplied CAD model, errors cannot be missed due to misreading of drawings.

convinced of its pedigree by the fact that the Ford Motor Company have recently selected it to be installed in all their plants world-wide. But what attracted him to it initially was its very powerful capabilities for inspecting complex surfaces and comparing machined results directly to a CAD Master Model. Put in simple terms, a customer designs a part on his CAD systems and supplies Jet with a CAD master model. That model is used in 2 ways. Duct software uses the model to generate 3D machining instructions to manufacture the part at the relevant CNC Machining centre. Simultaneously PC DMIS software uses the same CAD model to inspect the machined part, automatically generating CAD “nominal” data, removing what was typically one of the most time consuming and error prone areas of the inspection routine. Benefits of the package are twofold. Saving time allows for faster, more efficient inspection, relieving a bottleneck area and greatly increasing inspection capacity. Secondly since inspection is made against the original customer supplied CAD model, errors cannot be missed due to misreading of drawings.

JETS STAYS ONE STEP AHEAD

In today’s world of tight deadlines, rapid response is a distinct advantage to keep you ahead of the competition. Here, Jet’s Managing Director, Mark Kirby is pictured setting off to deliver a newly manufactured “plank” to the Prost Formula One Team Headquarters in Magny Cours, France. Having the facility to fly the part to its destination, Jet Blades was able to meet a deadline that put the goods in the customers hands in time for the first Grand Prix of the season. “Planks” are found under all Formula One racing cars, introduced as part of the safety measures to reduce the cars performance by negating the ground effect and hence reducing the speeds at which the cars could safely negotiate a circuit. Despite the fact that they are made from compressed wood and are simple in appearance,the machining tolerances are very tight and closely controlled as Michael Schumacher found out to his cost when disqualified from the Belgian Grand Prix for having too thin a plank on his car! Mark, who is a qualified multi-engine pilot, admitted that aeronautical delivery was rare, but a real time-saver on this particular occasion. He commented, “It brought a whole new meaning to ‘just in time’ and I did get some rather strange looks at the airfield whilst trying to manhandle the ‘plank’ into the plane, but meeting the customer’s delivery deadline made it worthwhile!”

JET SIGNS OFF ORDER ON THE NET

When Jet Blades recently won the order to machine fuselage patterns for the Israviation ST-50 all composite executive aircraft (pictured), the first challenge was how the two companies should exchange information regarding job detail and feedback quickly and cost effectively.

The Internet provided the solution. After brief technical consultation with Israviation, all CAD data was downloaded direct from Israel via the net

To keep the customer abreast of proceedings, digital photographs were transmitted back to Israel via the net providing a visual as well as written progress report.

Jet Blades & Engineering Ltd., Torrington Avenue, Coventry CV4 9HN.

Tel: 01203 466841 Tel 01203 467036 Fax: 01203 471215

e-mail: [email protected]

Latest Articles

Motivational Inspirational Speaker

Motivational, inspirational, empowering compelling 'infotainment' which leaves the audience amazed, mesmerized, motivated, enthusiastic, revitalised and with a much improved positive mental attitude, state of mind & self-belief.